High-density polyethylene is that super slick plastic that is used to make things like cutting boards, milk jugs, and gas cans. It’s also a very interesting material to use on the CNC because they make it with layers of colors. So for example, you can buy a sheet of red/white/red or blue/white/blue and that’s just what I did. I got the blue in 1/4″ and the red in 1/2″. I also picked up two special bits called O-flute bits which have a single large flute and a special coating to help turn the plastic into chips instead of a big melted mess.

My first project was an attempt at making an United States flag in the shape of the continental US. All CNC projects start with a lot of computer time and to help decrease the effort required, I bought an SVG file of that from Etsy. But as I started working with it, I realized that the flag was not accurate. I use an online calculator when I make flags and I was quickly able to verify so many problems that I ended up redrawing the flag from scratch. I was still able to make use of the US outline but that required work too to decrease the detail enough that it could be cut out cleanly but not so much that it looked like too simple.

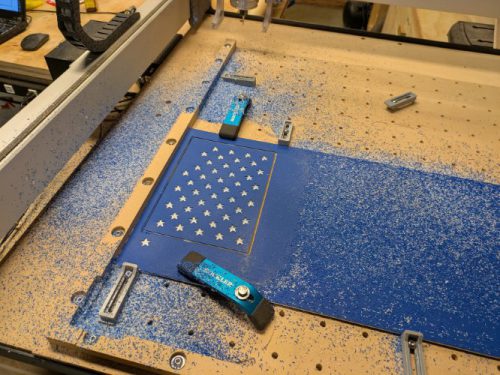

I began with the blue/white/blue sheet and nervously cut out the stars. I had looked up some feeds and speeds for cutting this material with my new bits and thankfully it worked well. I used an 1/8″ bit to remove most of the material and a 1/16″ bit to clean up the fine detail. The star below the cutout was my first test and then I left off the two inside the cutout because they wouldn’t be seen in the end anyway.

On the thicker red/white/red sheet, I pocketed out an area for the union to sit into and then also carved off the top red layer on all the white stripes.

Gluing the union onto the base flag was a challenge because nothing sticks to this, but I found some epoxy that worked. Apparently there is also some super glue that you can use if you have the right additional chemical to help it bond to HDPE.

After the epoxy had set, I nervously started the program to cut out the shape of the US.

After that it was just a little cleanup to remove the tabs of material that I left so that the piece wouldn’t fly out when it was cut all the way through.

I love the way it turned out and it’s neat to be done with a project at this point instead of having to apply finish. If I did it again, I think I would smooth out the US outline more and shift the flag image to the left so the ratio of blue to red/white looks a little better.

I’m not really in the business of selling stuff, but this is a fun project that I’d like to do more of. If you want one, let’s chat. The material cost is high, but I think I could make them for about $75 each.