As we approached Halloween, we went through a lot of ideas for Elijah’s costume. Since we haven’t done trick-or-treating for the last couple of years, we decided to let him get an actual costume. He chose to be the green ninja from Lego Ninjago. I couldn’t resist making part of his costume so I set out to make a dragon sword to go with it.

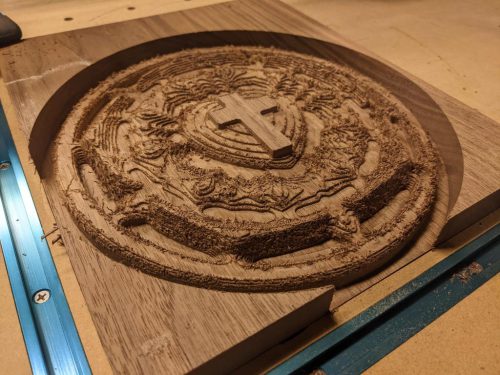

I wouldn’t have gotten far if I hadn’t found an existing model, but luckily Thingiverse came through for me. I pulled that model into Fusion 360 and spent hours trying to figure out how to cut it nicely on the CNC machine without taking forever. I was able to apply a lot of learnings from my Luther Rose project.

The final product was carved out of a scrap 2×4 and I did it in two separate halves. If I had it to do over again, I think I would learn how to program in a cut that I can flip over halfway through because the seam between the two pieces was visible even in the finished product.

Once the pieces were glued together, I applied a few coats of a filler primer with sanding in between. The sanding took a long time with all the nooks and crannies. Thankfully, Elijah got interested in the project at this point and helped with the sanding.

We finished it off with a couple coats of high-quality gold paint. The final product looked amazing! It makes me want to do another one at the biggest scale that my CNC could handle…